Injection & Blow Molding

Quality Made Us Global

Global Plastics: Industries and Products

Automotive Parts:

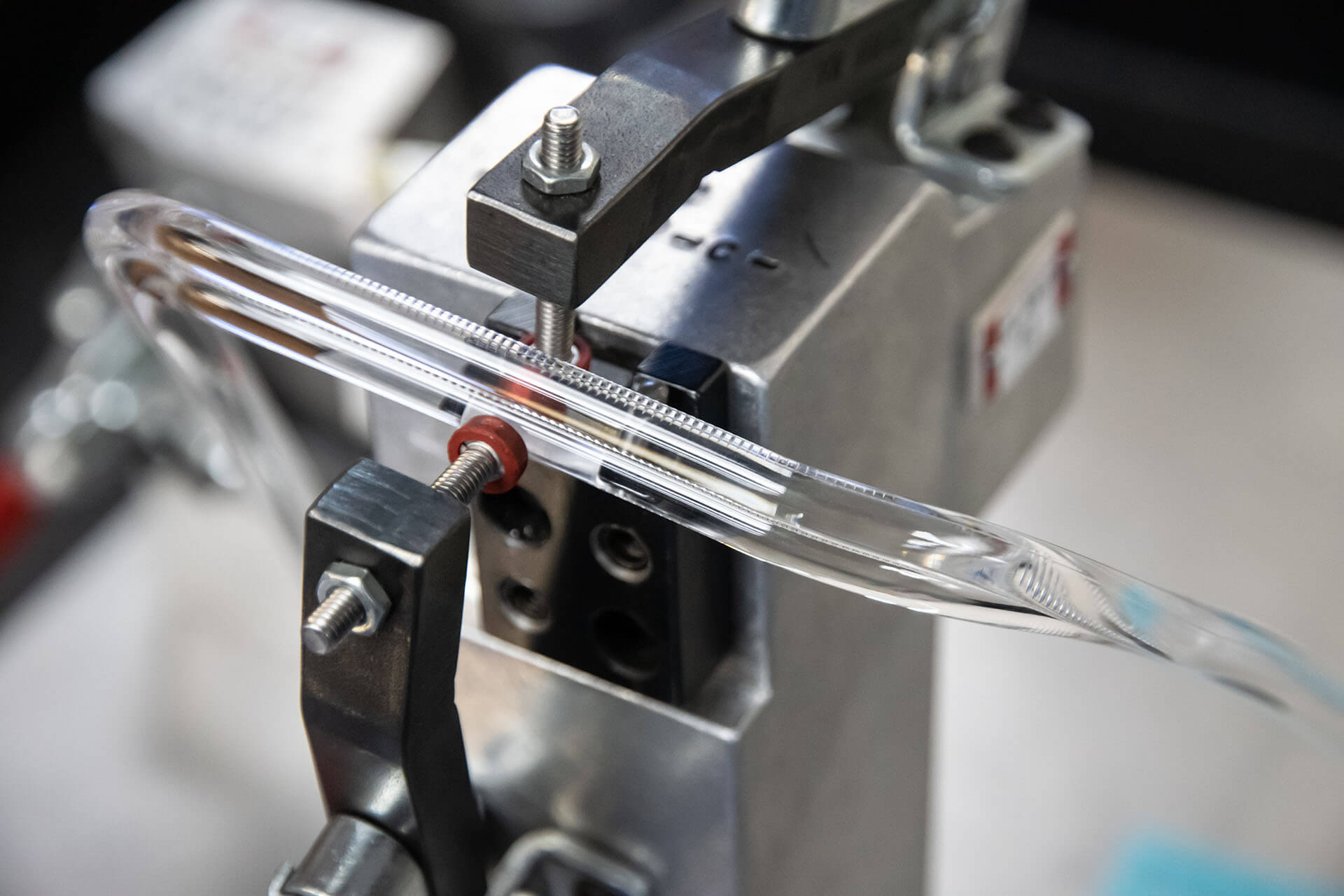

Interior panels and components (A, B, and C pillars), instrument panel parts, consoles, cup holders, decorative trim, and overhead entertainment systems; exterior fascia and bumper components, fuel doors, and lenses for lighting (headlights, turn signals, high-mount stop lights, taillights, brake lights, and so on); and various drivetrain and mechanical parts, including emissions controls, fuel delivery system components, and a variety of fasteners.

Medical Devices and Parts:

Chemical test strips (cholesterol, HDL, LDL, and triglycerides); catheters, biopsy, check valves, and fluid delivery components; chemical meters, urology pumps, and orthopedics.

Commercial Sector:

Collector box and moisture trap for high-efficiency furnaces; spools and reels for wire cable, commercial packaging, electronic housing, quick scrubber (complete assembly); scrubber for rubber membrane roofing systems.

Food Packaging:

Custom and stock consumer packaging such as caps, closures, and bottles.

Cost-Effective Plastic Parts: Global Plastics Production Expertise

Efficiency and Quality: Global Plastics Precision-Machined Experience

Whether your plastic product goes directly to the consumer or is a part or component of a larger assembly, Global Plastics will apply the same rigorous process in designing the product and the process that will meet your requirements at the production volume you need. Our performance commitment to efficient manufacturing principles at every stage means we relentlessly pursue continuous improvement to achieve optimal efficiency and quality. The result is a cost-benefit you’ll be hard-pressed to find at many suppliers.

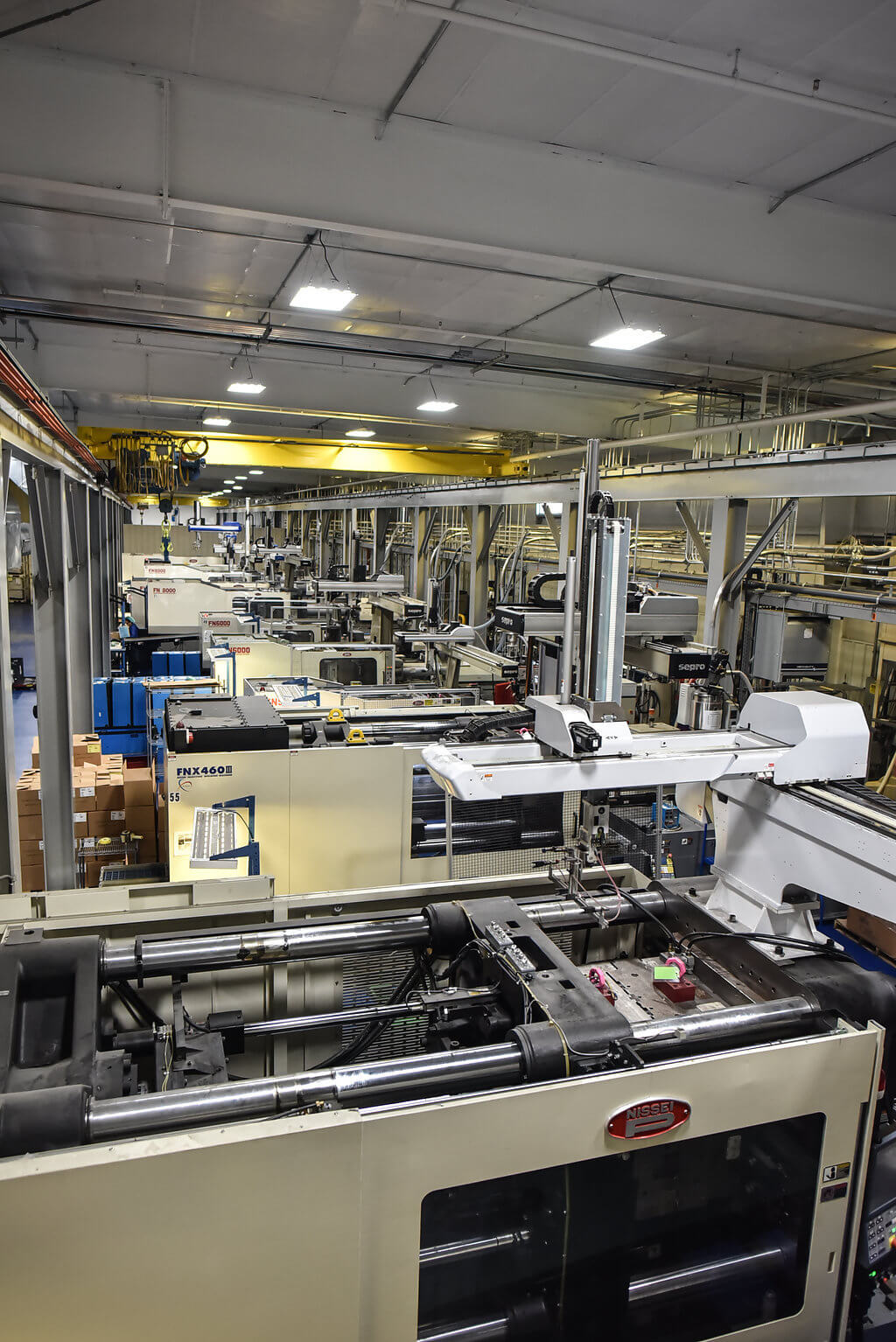

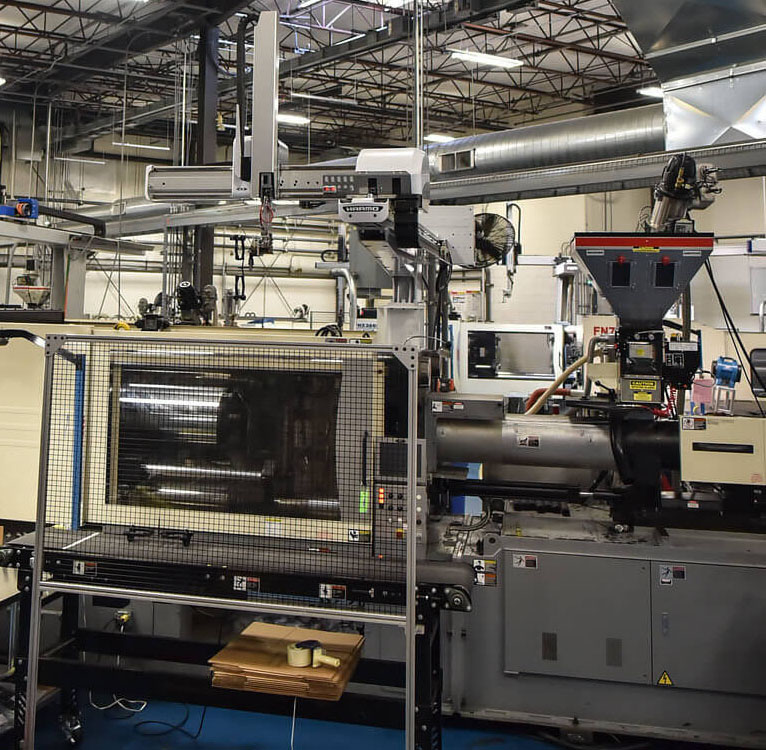

There are a myriad of choices that go into achieving these results. It could be choosing the best machine for the job, such as a toggle clamp injection press versus a ram clamp press, depending on the level of precision needed in the final product. With our fleet of more than 70 injection molding machines, you can rest easy knowing we’ve got the right machine for your project. It will include choosing the suitable raw material for the product’s intended application from the variety of thermoplastic options available today. Customized service for every client means collaboratively and transparently identifying and dealing with all such decision points.

Injection Molding 101: The Basic Process

You need a particular custom plastic part that will be used in a more extensive product assembly. It’s a relatively simple piece, but you need many of these parts—whether in the hundreds or the millions each year. You determine that the injection molding manufacturing process will likely be the most cost-effective way to meet your needs. Unlike many injection molding plants, Global Plastics creates custom parts.