Mold Transfers

Quality Made Us Global

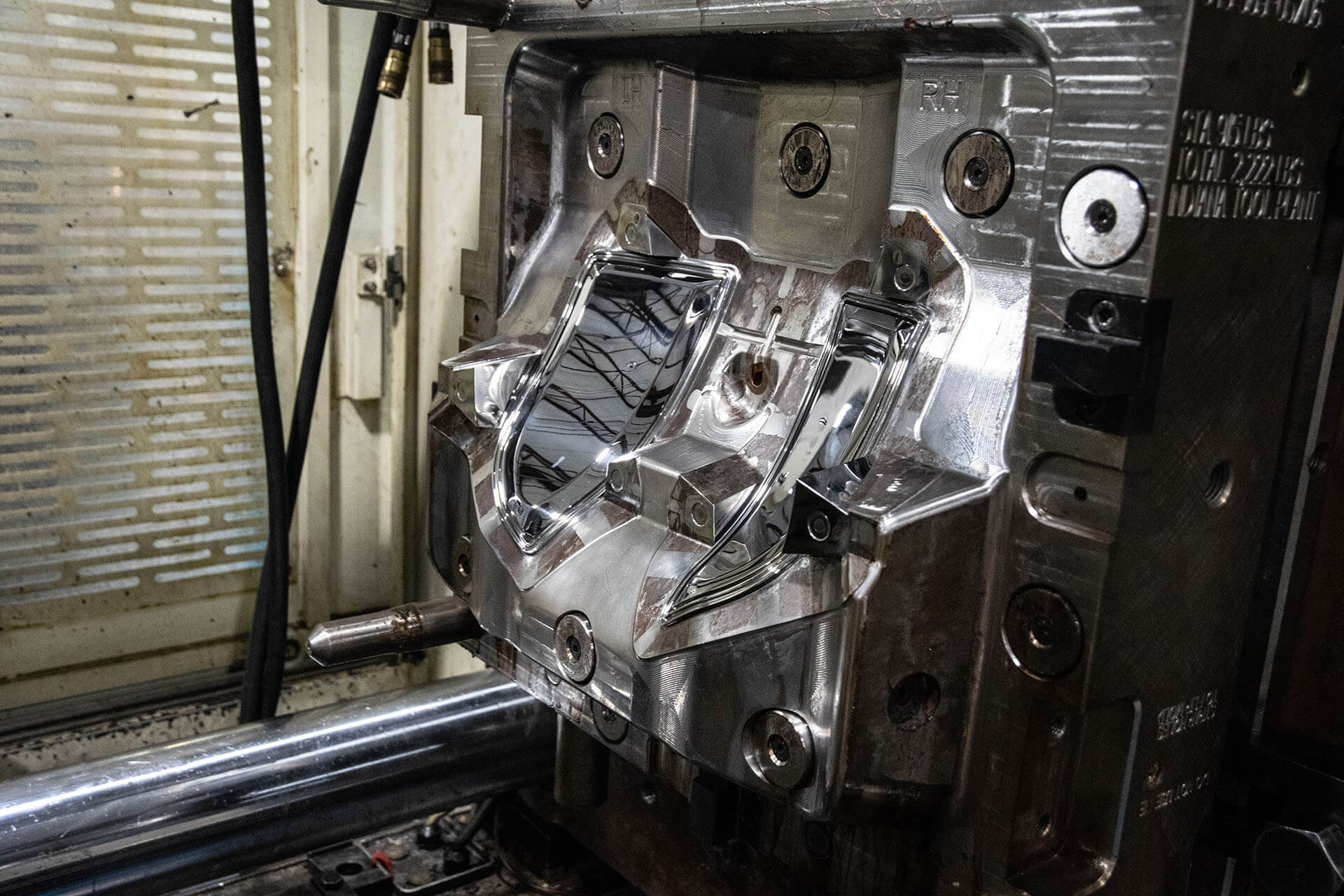

Injection Molding

Injection Molding Die & Mold Transfers to Global Plastics

Planning for Injection Molding Die Mold Transfers

To use a well-worn management adage, the key to a successful mold transfer is to “plan the work, then work the plan.” But all your planning will be wasted if you don’t choose the right injection molding partner to receive your mold transfer. Whatever your other criteria may be when choosing an injection molding partner, be sure to evaluate any potential partner on their experience and readiness to handle a mold transfer. At Global Plastics, we realized early on how the injection mold transfer process becomes a major pain point for many companies. We’ve developed deep expertise in how to implement efficient, accurate mold transfers so companies don’t experience any manufacturing downtime—as long as they plan the work, then work the plan. Putting in this extra effort up-front before a mold transfer ensures you’ll gain all the benefits of stress-free mold transfer.

Overcoming Transfer Hesitancy

Many companies have experienced such nightmare scenarios with mold transfers that they’re actually willing to continue working with a service provider that is far more expensive than they want, or whose customer service and work is subpar because they want to avoid all the hassles and headaches of the mold transfer process. After all, a mold transfer can go completely sideways in all sorts of ways, especially if your company hasn’t planned properly for the transfer, or if the new service provider doesn’t have their act together when they receive the mold.

The nightmare you want to avoid is transferring your mold, then getting a call from the new injection molding partner that the mold needs significant work and won’t be ready to run for some period of time. Meanwhile, you run out of essential plastic parts or components needed and your manufacturing production line has to shut down. Lost time, lost money. But it doesn’t have to be that way, and Global Plastics can help because we’re experts at mold transfers.

There are a number of reasons why a mold transfer might need to happen, including the following:

- Your current injection molding partner is going out of business.

- Your current service provider’s rates are just too expensive.

- Customer service with your current provider is sorely lacking.

- You want an injection molding facility in a better geographic location.

- You’re not happy with the quality of plastic parts and components you’re getting.

- You are experiencing supply chain interruptions or deficiencies due to the service provider

These reasons for transferring your tooling equipment to another service provider are a source of stress to begin with. The last thing you want is to add to the stress with a poor mold transfer experience.

Mold Transfer Planning Guide

Use this handy mold transfer planning guide to make sure your company is ready for the mold transfer when the time comes. Bridging the gap between one injection molding partner to another efficiently and seamlessly takes careful planning on your part, as well as coordinating with both service providers to get it right.

Select the New Injection Molding Partner

As you explore new partners to meet your injection molding needs, put mold transfer capabilities front and center. You’ll want to feel confident about the new partner and work closely with them in the planning process as you sign a contract with them, including nailing down a detailed transfer and production schedule.

Gather Mold Documentation

Be sure to collect every bit of documentation you can so your new service provider will have all the information and key data they need about your mold and tooling equipment. Line up the following:

- Up-to-date design specifications, blueprints, and prototype for the mold and all component parts;

- available spare parts (hopefully a full set);

- proof of current condition (preferable documented with photographs);

- material designations;

- performance specifications and operational parameters;

- inspection and certification documents;

- any 3D data design files for mold and part design;

- and as much information as possible about the part being made, including usage as well as any secondary operations or assembly requirements. Include a sample of last shots from the mold when transferring to the new service provider.

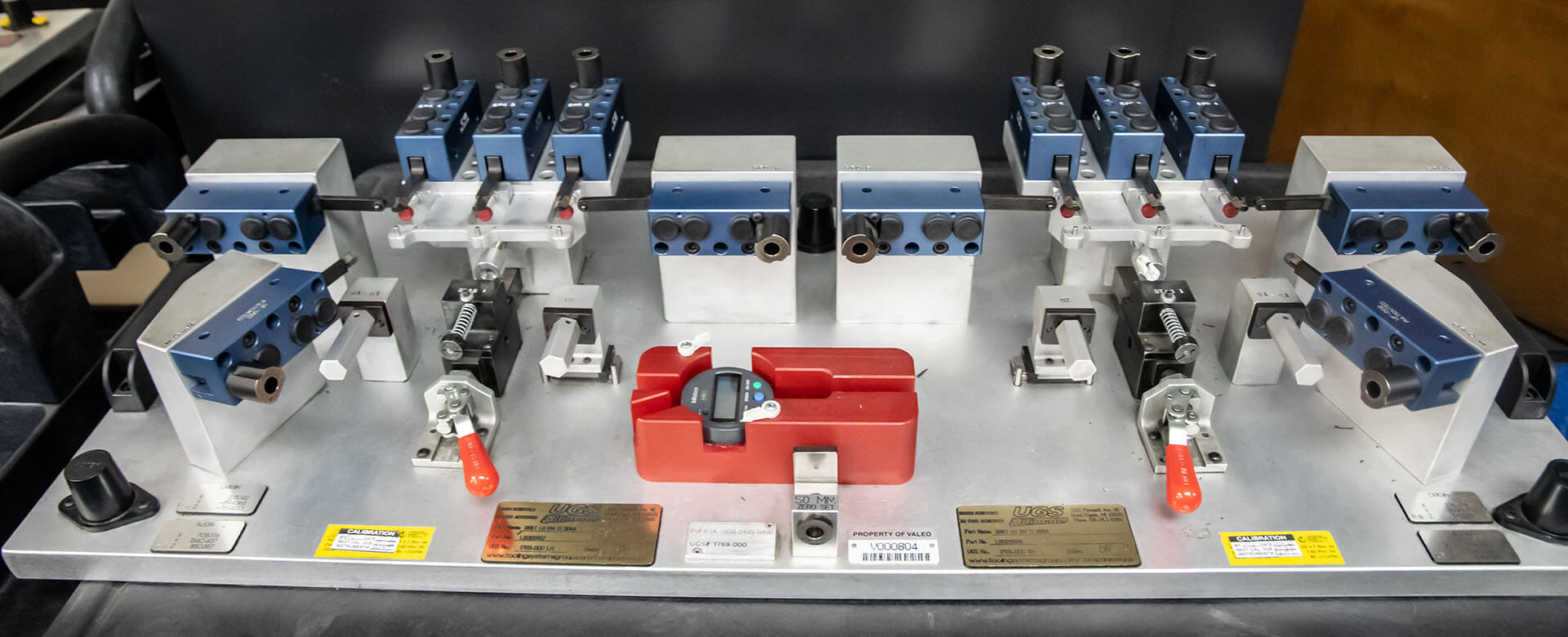

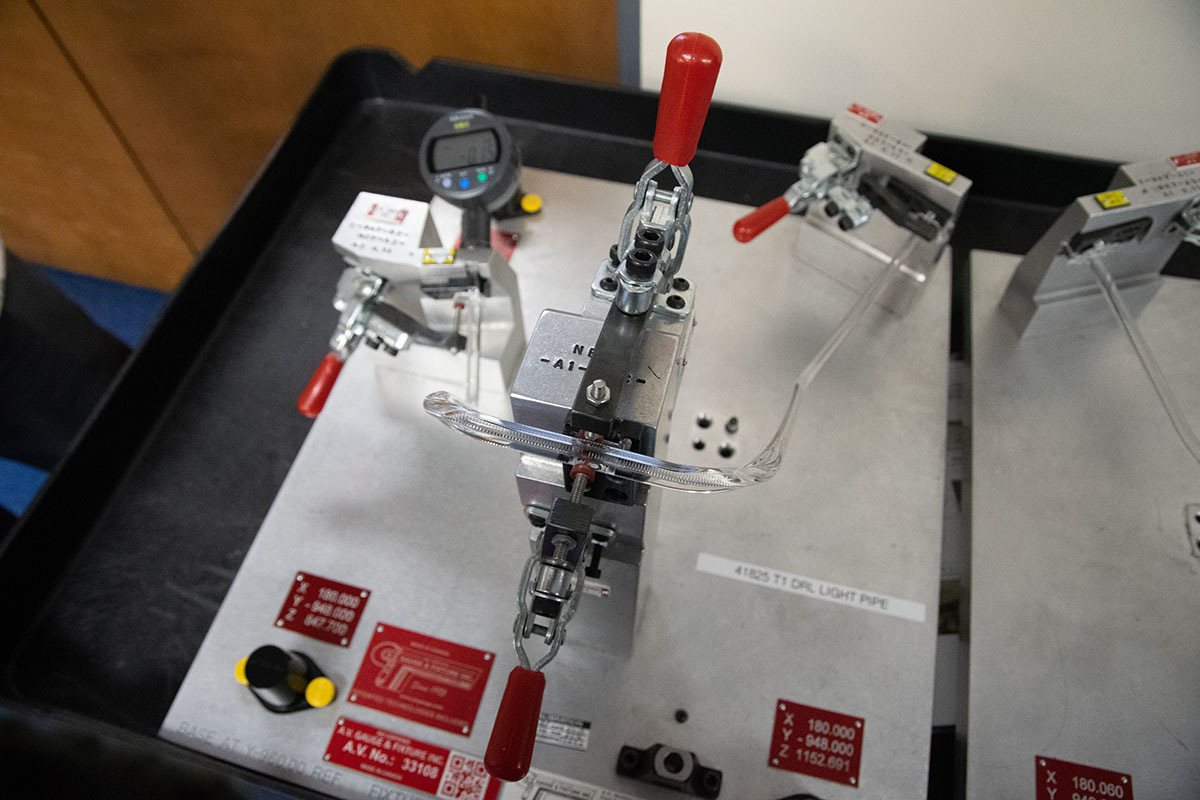

Quality Inspection/Tool Audit

Ideally, your current partner would conduct a thorough tool audit to generate quality assurance documentation of the current condition of your equipment and related components. The fewer quality issues or surprises going into the mold transfer process, the better.

Adequate Advance Inventory

There’s going to be downtime during the transfer process before production can begin at your new service provider’s facility. This means you want to build up several weeks’ worth of stock if other manufacturing processes depend on plastic parts or components made with the mold, which also means you want those extra runs scheduled well in advance. We highly recommend this procedure, if possible.

Tooling Transfer Prep

Advise your current service provider to prepare your tooling for transfer. The mold and all associated parts should be thoroughly cleaned, free of raw materials. Water lines should be empty and a protective coating applied to everything. Pack the mold and components into a crate or onto a palette with appropriate protection to prevent damage during transport.

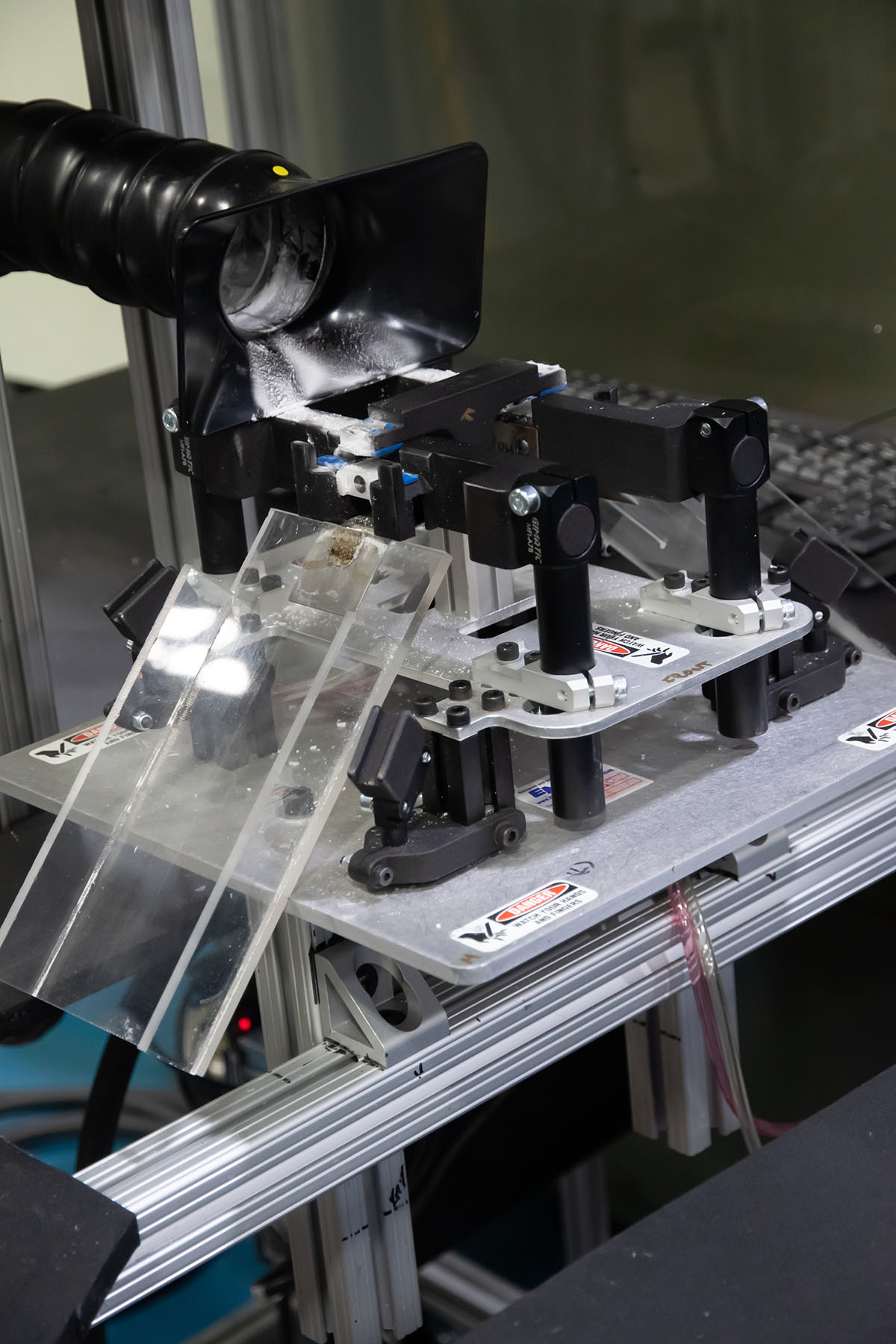

Pre-Production Testing

Your new injection molding service provider will need to clean, inspect, and test everything in order to verify the mold equipment is ready to commence full production to guarantee quality.

Global Plastics: Your Trusted Mold Transfer Partner

The success of a mold transfer depends on a variety of factors. In the event that a substantial retooling is needed, be sure to factor that into the schedule. As you can see, a mold transfer is a complex process, but think of it as investing in a key asset critical to your business success. When you work with Global Plastics on a mold transfer project, you’ll rest easy knowing our decades of injection molding experience includes specializing in mold transfer projects. We go the extra mile to ensure smooth, efficient, seamless transfers to keep your business on track.

When the need for a mold transfer appears on the horizon, Global Plastics is ready to start a conversation with you. Learn more by getting in touch with us using the contact us form on our website.