Prototyping

Prototyping and Tooling at Global Plastics

Rather than relying on multiple vendors where one service provider handles your tooling and another provider executes injection molding production runs, Global Plastics offers a full-service, in-house tooling department. This means only one partner who is with you every step of the way, providing all the services you need from product design to prototype tool to production tool and production runs. This gives you easier visibility into and control of the entire process, including careful tool management over the entire tool life cycle. Our soup-to-nuts capabilities for any injection molding project provides quality outcomes for every client customer, and we’ll do the same for your company as well.

An In-House, Full-Service Tooling Department

Rather than relying on multiple vendors where one service provider handles your tooling and another provider executes injection molding production runs, Global Plastics offers a full-service, in-house tooling department. This means only one partner who is with you every step of the way, providing all the services you need from product design to prototype tool to production tool and production runs. This gives you easier visibility into and control of the entire process, including careful tool management over the entire tool life cycle. Our soup-to-nuts capabilities for any injection molding project provides quality outcomes for every client customer, and we’ll do the same for your company as well.

Prototype Tooling for Testing Purposes

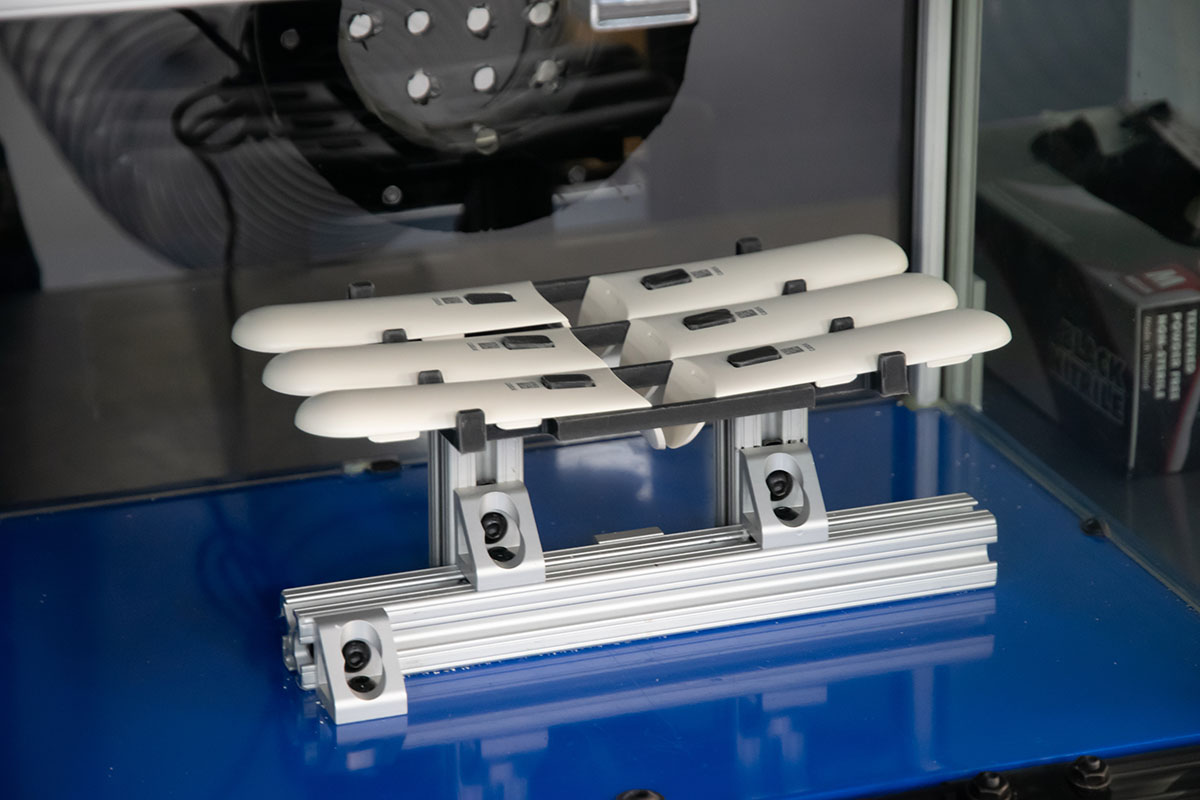

Tooling a mold in steel for production is an investment. The prototyping process within product development is how we ensure the production mold will meet the requirements for your injection molded plastic part, component, or product. Aluminum is much softer than steel and easier to machine, which makes it a very cost-effect material for prototype tooling. An aluminum mold can be tooled in a fraction of the time and cost of standard steel production tooling. This prototype mold is good for low-volume production runs of less than 10,000 pieces, which is more than enough for testing the mold to ensure your injection molding project will meet your quality standards. Prototype designs will reveal any potential issues that need to be addressed before you make the investment in full production tooling.

Rapid Prototyping for Low-Volume Production Runs

In addition to being a cost effective testing process in the product development process, some applications only require low-volume production runs to meet your needs, and especially when time is of the essence. Our rapid tooling capabilities will drastically shorten the time frame for getting the plastic parts or components you need. An aluminum mold in this scenario won’t last the way a steel mold does, but it gives you what you need when speed and efficiency benefits are a top priority.

In-House Tooling for High Volume Production Runs

When the prototyping process is complete, then it’s time to make the investment into tooling a final production mold for high-volume injection molding projects. Steel molds have a much longer life than aluminum molds and will undergo our rigorous tool management and maintenance protocols to extend mold life even further. A few of the more common types of steel used for standard injection mold tooling include the following:

P20 Steel:

This is a pre-hardened, low-alloy steel with good toughness at moderate strength levels. It is one of the most frequently used mold materials for plastic injection molding.

S7 Steel:

Stainless Steel:

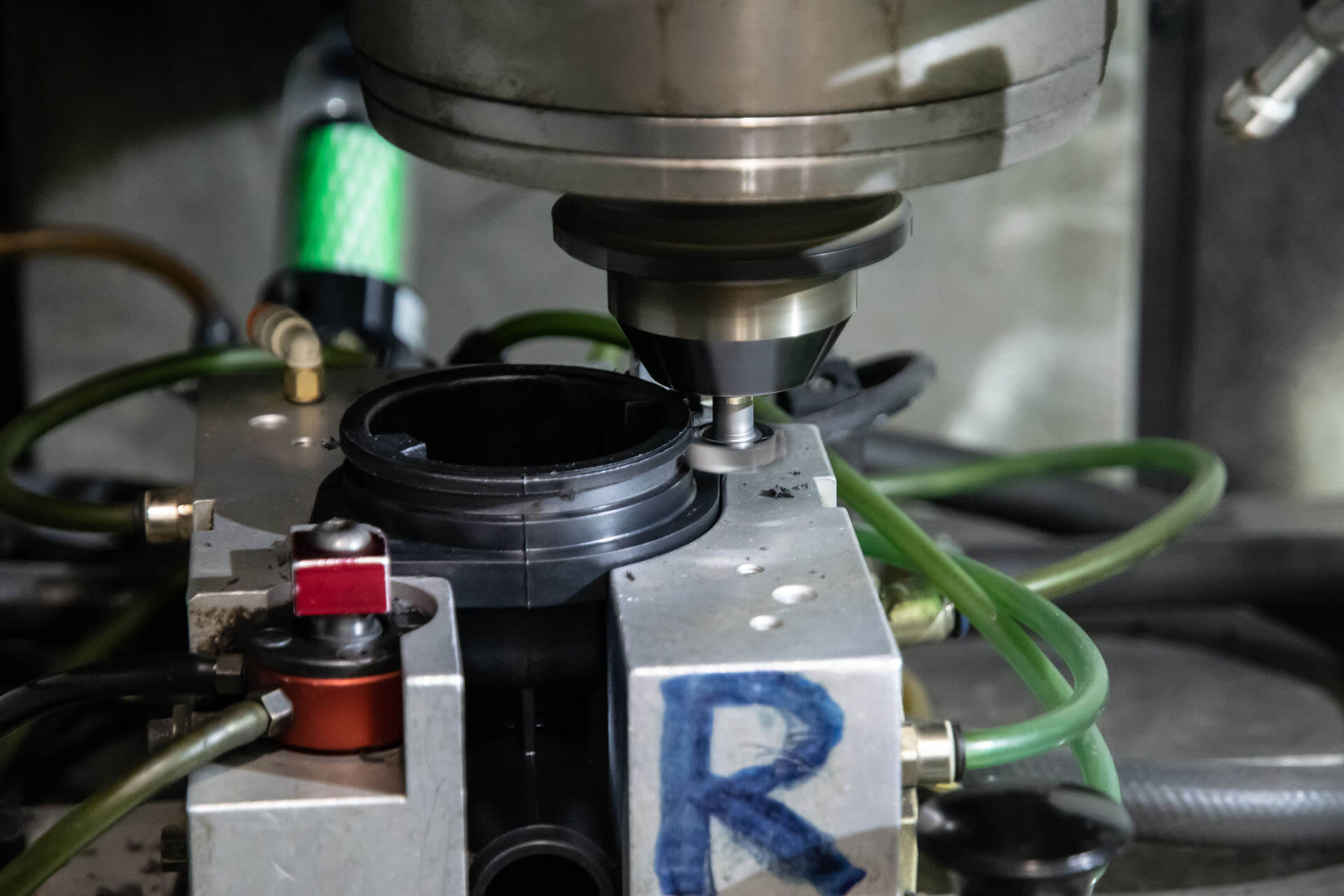

The specific machining process used will depend on a variety of factors, but the three techniques we rely on most at Global Plastics include the following:

CNC Machining:

Wire EDM:

Programmable EDM:

Our custom tooling department’s expert staff and state-of-the-art equipment can implement multi-cavitation, advanced gating systems, and efficient cooling for your injection molding project when needed.

Your Injection Molding Partner: Global Plastics

Global Plastics works with every customer client in a manner that is collaborative and transparent. Our goal is to meet your needs with an optimal mix of speed and efficiency for cost-effective quality plastic parts, components, and products that exceed your expectations. As we work with you through product design, prototyping, tooling, and production, constant communication and robust reporting keeps you informed every step of the way. If you’re interested in learning more about injection molding with Global Plastics, we invite you to get in touch using the contact us form on our website. We look forward to meeting you and discussing how we can meet your needs.